Understanding the HM88 Series: Features and Benefits

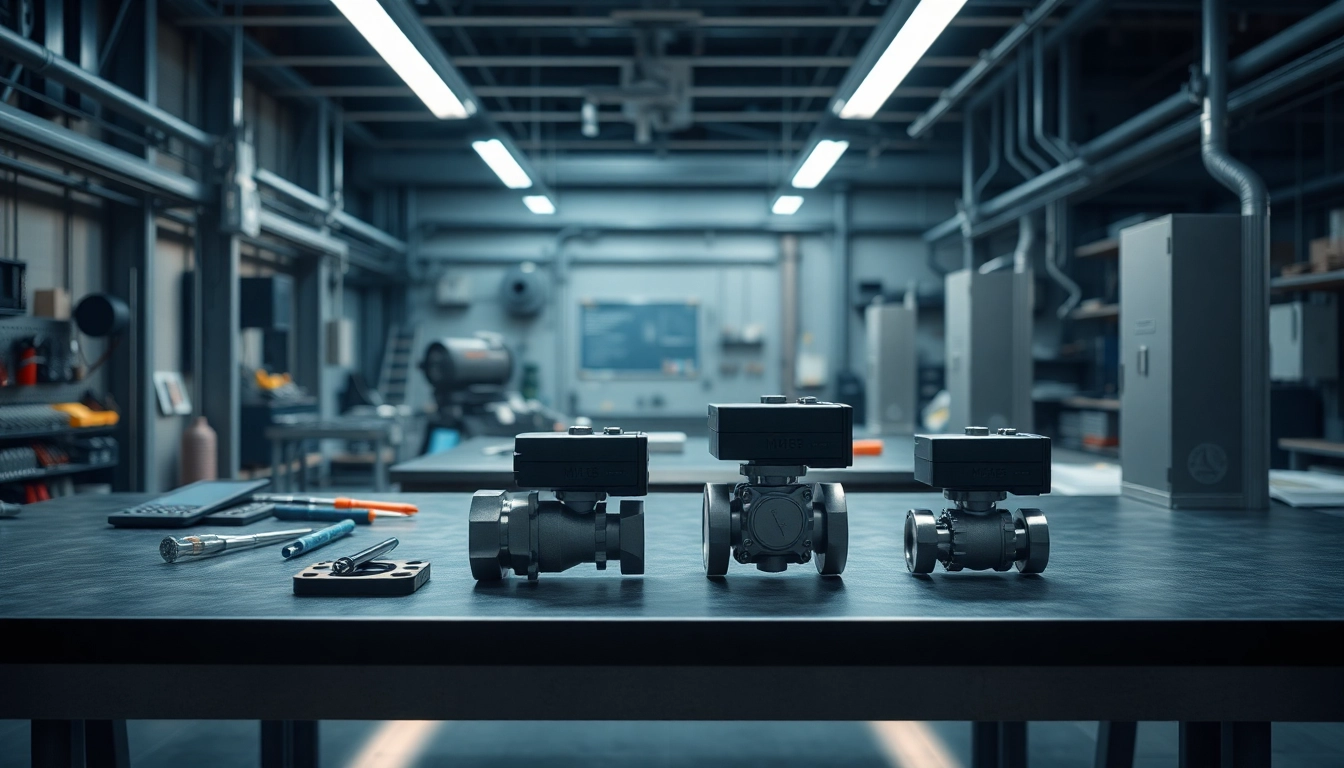

The HM88 Series of valves stands as a cornerstone in modern engineering due to its innovative design and reliable functionality. These valves are particularly renowned for their application in fluid control systems, ensuring precision and efficiency across various industrial settings. When exploring options, hm88 provides comprehensive insights into the features and specifications that make this series a preferred choice among engineers and technicians.

What Makes HM88 Stand Out in Modern Engineering?

One of the defining characteristics of the HM88 Series is its robust construction coupled with exceptional performance efficiency. The valves are designed for high-pressure applications, making them ideal for challenging environments where reliability is paramount. The close-coupled mounting design allows for seamless integration with differential pressure transmitters, enhancing measurement accuracy and response time. These features collectively contribute to reduced downtime and improved operational efficiency in manufacturing processes.

Key Specifications of HM88 Valves

- Material: High-grade stainless steel for corrosion resistance.

- Pressure Rating: Suitable for high-pressure applications up to 6000 psi.

- Temperature Range: Operates effectively in temperatures ranging from -40°F to 250°F.

- Flow Coefficient: Optimized for maximum flow capacity while minimizing pressure drop.

- Size Options: Available in various sizes to fit different piping requirements.

Applications of HM88 in Industrial Settings

HM88 valves are engineered to meet the demands of various sectors including oil and gas, chemical production, and water treatment. Their reliability in controlling fluid flow is indispensable in processes that require strict compliance with safety and operational standards. Applications commonly include:

- Control of hydraulic systems in machinery

- Regulating steam and gas in energy production facilities

- Fluid handling in laboratory and research settings

- Utilization in water distribution and wastewater management systems

Choosing the Right HM88 Product for Your Needs

Selecting the correct HM88 valve requires careful consideration of the specific requirements of your application. Various factors can influence your choice, ensuring optimal performance and compliance with industry standards.

Factors to Consider When Selecting HM88 Valves

- Application Type: Assess whether the valve will be used in high-pressure or standard conditions.

- Fluid Type: Consider compatibility with the fluids being handled, especially corrosive substances.

- Size and Dimensions: Ensure that the selected valve fits within the existing system infrastructure.

- Maintenance Needs: Evaluate ease of access for potential servicing and routine maintenance.

Comparing HM88 with Competitor Products

When comparing HM88 to competitor products, it is essential to analyze performance metrics such as flow capacity, pressure ratings, and material durability. Many competitors may offer similar valves, but HM88’s integration of advanced engineering techniques and materials often results in lower failure rates and longer operational lifespans. Understanding the unique selling points of HM88 can be a decisive factor in making an informed purchasing decision.

Common Use Cases for HM88 Series Valves

Real-world applications of HM88 valves highlight their versatility and reliability. Common scenarios include:

- Operating as on/off controls in oil drilling rigs

- Regulating temperature and pressure in chemical reactors

- Managing fluid delivery in pharmaceutical manufacturing processes

Installation and Maintenance of HM88 Valves

To ensure the effective performance of HM88 valves, proper installation and ongoing maintenance are critical. Understanding the recommended practices can extend the longevity and reliability of these valves considerably.

Step-by-Step Installation Guide for HM88

- Preparation: Gather necessary tools, including wrenches and safety equipment.

- Check Compatibility: Confirm that the valve is suitable for the intended application.

- Align the Valve: Position the valve correctly within the piping system, ensuring that flow direction markings are observed.

- Tighten Connections: Use appropriate torque settings to fasten connections to avoid leaks or failures.

- Test the System: Activate the system and monitor for leaks or irregularities.

Best Practices for Maintaining HM88 Products

Regular maintenance of HM88 valves can prevent unexpected failures. Best practices include:

- Conducting periodic inspections for wear and tear.

- Cleaning the valve internals to prevent clogging.

- Replacing seals and gaskets as necessary to maintain pressure integrity.

- Keeping detailed records of maintenance activities for compliance and tracking.

Common Issues and Troubleshooting HM88 Valves

Even with diligent maintenance, issues may arise with HM88 valves. Common problems include:

- Leakage: Often caused by worn seals or improper installation.

- Pressure Drops: May indicate blockages or incorrect sizing of the valve.

- Sticking Mechanisms: Can result from corrosion or debris build-up.

Identifying and addressing these issues promptly can enhance valve performance and extend service life.

Future Trends in Valve Technology and HM88 Innovations

The valve industry is on the brink of significant innovations that will redefine operational efficiencies. The HM88 series is poised to adapt to these trends, ensuring continued relevance and effectiveness in various applications.

Emerging Technologies Impacting Valve Engineering

Technological advancements, such as IoT integration for predictive maintenance, smart sensors, and automated control systems, are transforming how valves are utilized in industrial applications. These innovations allow for real-time monitoring and adjustments, enhancing efficiency and reliability.

How HM88 is Adapting to Industry Changes

HM88 is actively investing in research and development to incorporate new technologies into its products. The focus is on improving functionality while ensuring compliance with evolving safety and environmental regulations. Enhanced materials and designs are also being explored to address the challenges posed by increasingly aggressive fluid handling environments.

Predictions for Valve Solutions in 2025 and Beyond

By 2025, the demand for smart valves that can communicate with other system components is expected to rise significantly. Innovations in material science will likely lead to valves that can withstand higher pressures and temperatures, enhancing their applicability in extreme environments. The HM88 series aims to be at the forefront of these developments, delivering solutions that meet both current and future industrial needs.

Case Studies: Successful Implementations of HM88

The successful application of HM88 valves in various industries showcases their versatility and effectiveness in real-world scenarios. Through analyzing these case studies, we can understand the impact of these valves on operational efficiencies and safety standards.

Real-World Applications in Manufacturing

In the manufacturing sector, a prominent automotive manufacturer implemented HM88 valves in their hydraulic systems, resulting in a 20% improvement in response times and a significant reduction in maintenance costs. This case demonstrates how selecting the right valve technology can lead to tangible operational gains.

Client Testimonials on HM88 Performance

Clients across sectors have reported increased reliability and performance when utilizing the HM88 series. One chemical processing client noted, “Switching to HM88 valves transformed our operational efficiency. We’ve seen fewer failures and higher throughput.” Such feedback underscores the crucial role of effective valve solutions in enhancing productivity.

Analyzing the Impact of HM88 on Efficiency and Safety

The integration of HM88 valves into process systems has consistently shown to enhance safety protocols and operational efficiencies. By minimizing leakages and pressure drops, these valves contribute significantly to workplace safety and compliance with industrial regulations.